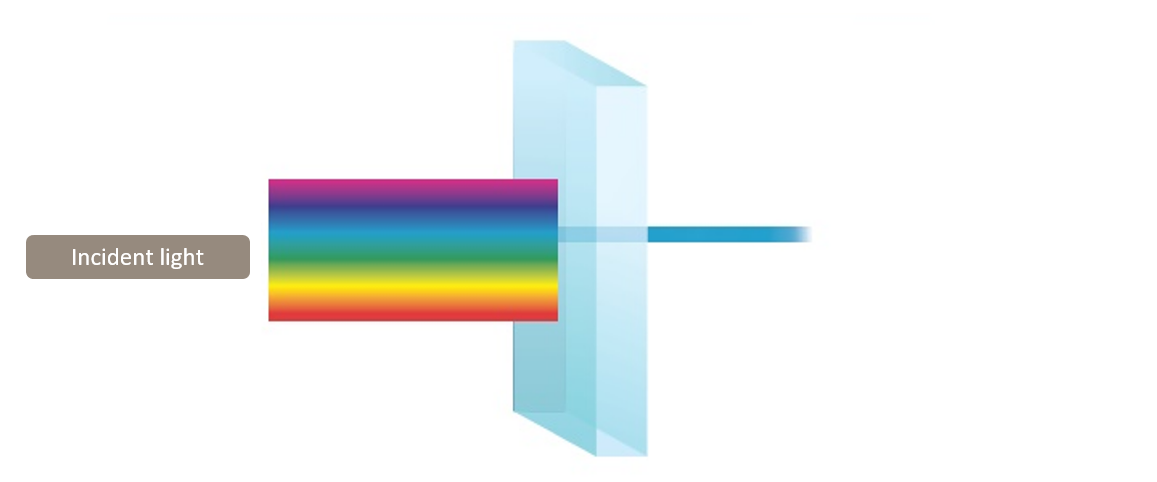

Optical thin films are made by alternately depositing multiple types of materials with different refractive indices on a substrate such as glass or metal. They control the transmission, reflection, and interference of specific wavelengths of light. Optical thin film technology is used in a wide range of applications, including lasers, optical filters, microscope lenses, and solar panels.

Koshin Kogaku Kogyo, a member of our group, produces multi-layer filters and their application devices using its proprietary technology. In this column, we will explain how Koshin Kogaku Kogyo’s proud technologies and products are used in everyday life.

What Is Optical Thin Film Technology?

Optical Thin Film Technology

Filters are used to control the transmission, reflection, and interference of specific wavelengths of light, depending on the purpose, such as “blocking ultraviolet rays” or “capturing only infrared light.”

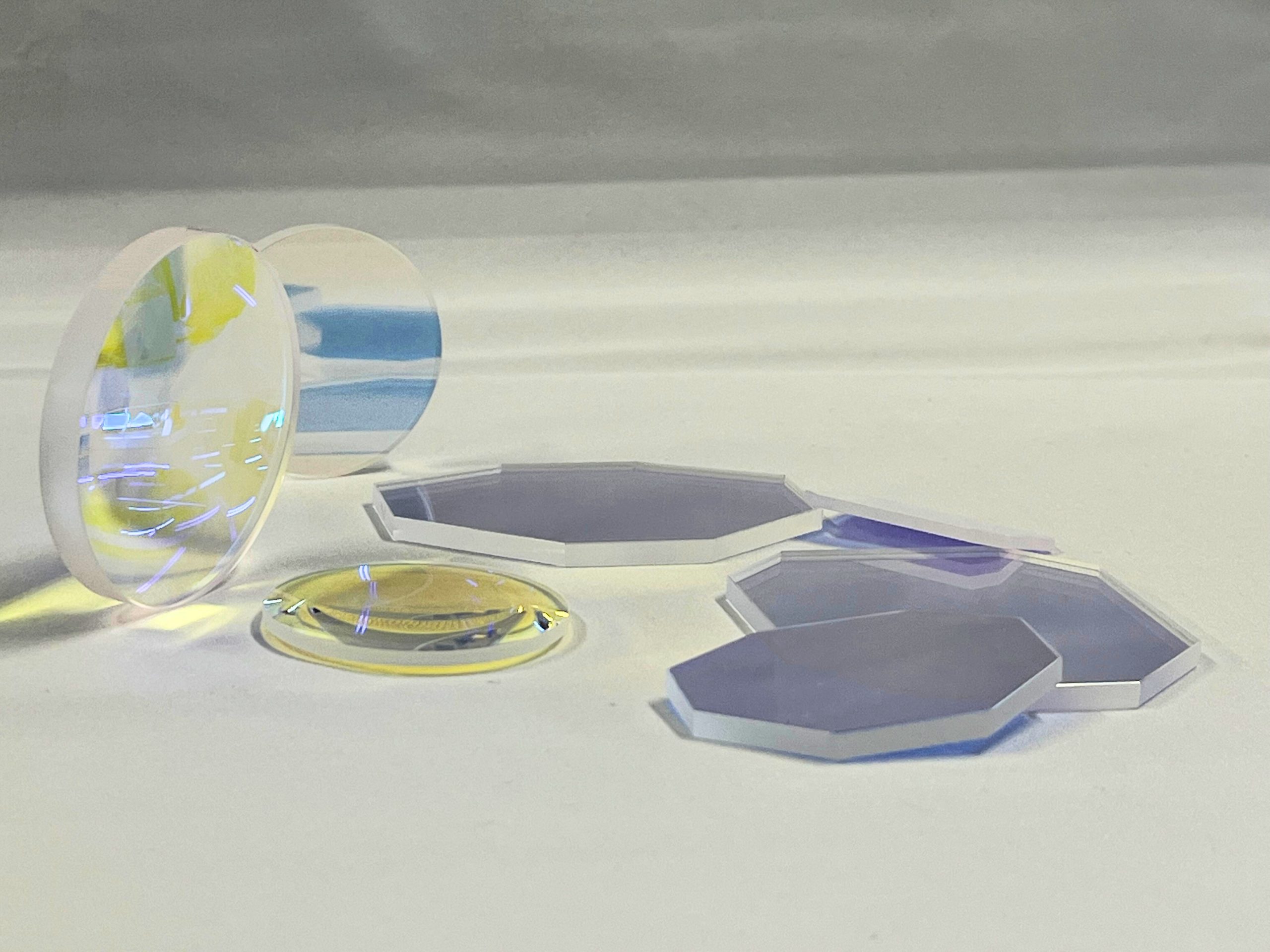

Optical thin-film technology involves laminating multiple types of materials with different refractive indices (such as metal oxides, fluorides, nitrides, etc.) into very thin layers on a substrate like glass or resin. Filter coatings are created by designing how many layers of each material are needed for the wavelengths that you want to transmit or block.

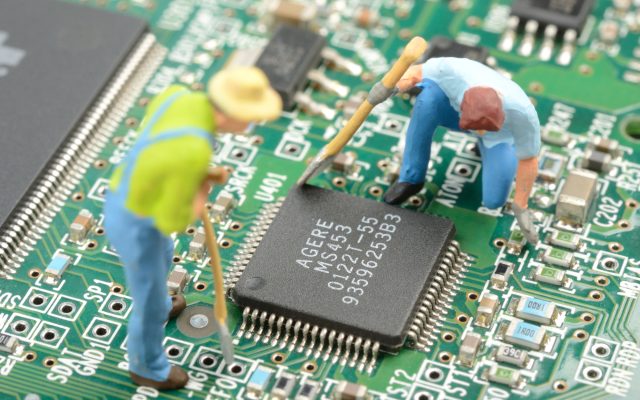

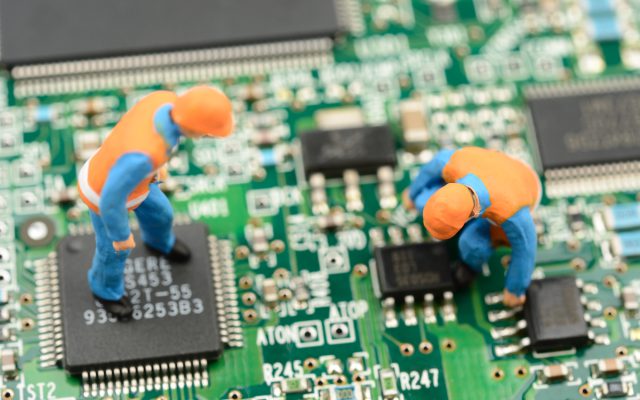

Vacuum Deposition Technology

When coating filters, Koshin Kogaku uses “vacuum deposition technology,” in which thin-film materials are heated to high temperatures in a vacuum chamber and then evaporated. Leveraging the know-how developed over many years, Koshin Kogaku has achieved stable control of the number of film layers by precisely managing the film thickness, even when stacking more than 300 layers of evaporated material.

Vacuum deposition technology is used in chemical analysis equipment as well as in pharmaceutical development.

In pharmaceutical development, custom multi-layer coatings allow analytical conditions to be tailored to the specific characteristics of the drug, which has the advantage of enabling efficient research and development.

Where Are Koshin Kogaku Filters Used?

Medical & Bio Business

Koshin Kogaku’s filters are used in the medical field for the analysis of blood, viruses, pharmaceuticals, etc., as well as in bio-research.

Biological Microscopes

When observing cells or tissues with a biological microscope, a filter that only allows light of selected wavelengths to pass through is required. For example, when observing cancer cells, placing a filter in the microscope that makes the cancer cells fluoresce makes it easier to identify their location.

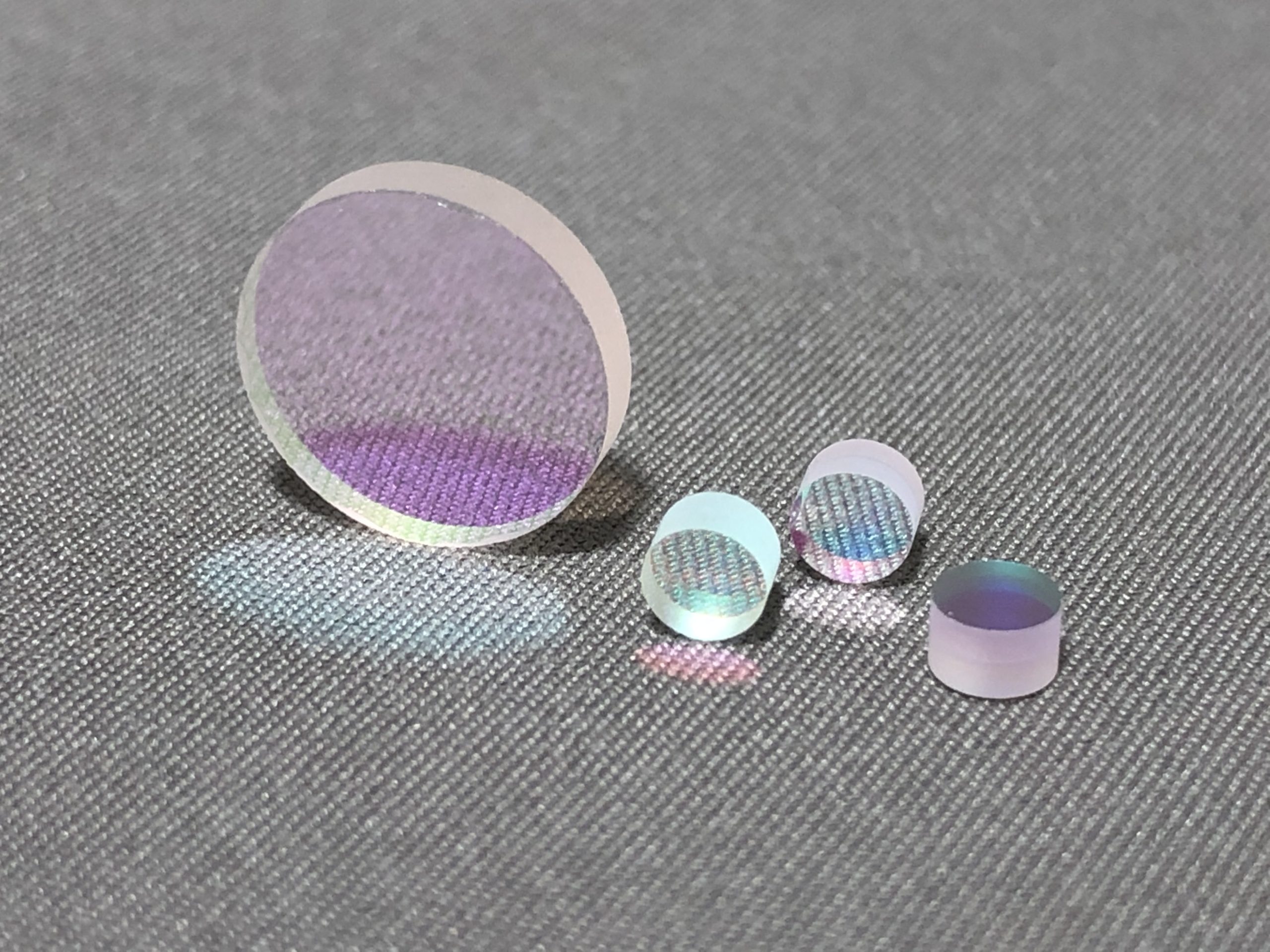

Koshin Kogaku Kogyo has developed a filter capable of detecting excitation light and fluorescence at different wavelengths, allowing a single filter to detect multiple substances. These filters are also used in PCR tests to detect viral and bacterial genes.

Product examples: Multi Band Pass Filter

Endoscopes

Endoscopes are used to observe the inside of the body. By using filters that remove unnecessary light, the contrast and resolution of images can be improved, making it easier to observe internal tissues in affected areas. Additionally, when filters that emphasize specific wavelengths of light are used, certain tissues and lesions can be more clearly visualized in endoscopic images.

Chemical Analysis Equipment

Chemical analysis equipment used to examine chemical composition and properties are applied in various fields, including chemical experiments, industrial process control, and pharmaceutical development. These devices use filters that emit light when certain pathogens are present in blood.

Video Equipment Business

Koshin Kogaku’s filters are also used in surveillance cameras installed outdoors and in commercial video cameras used both indoors and outdoors. These filters combine “environmental resistance,” which allows them to withstand the drastic temperature and humidity fluctuations of outdoor use, with “low reflectance performance,” which prevents strong external light, such as sunlight and artificial lighting, from entering the camera and causing internal reflections. This enables clear and accurate imaging.

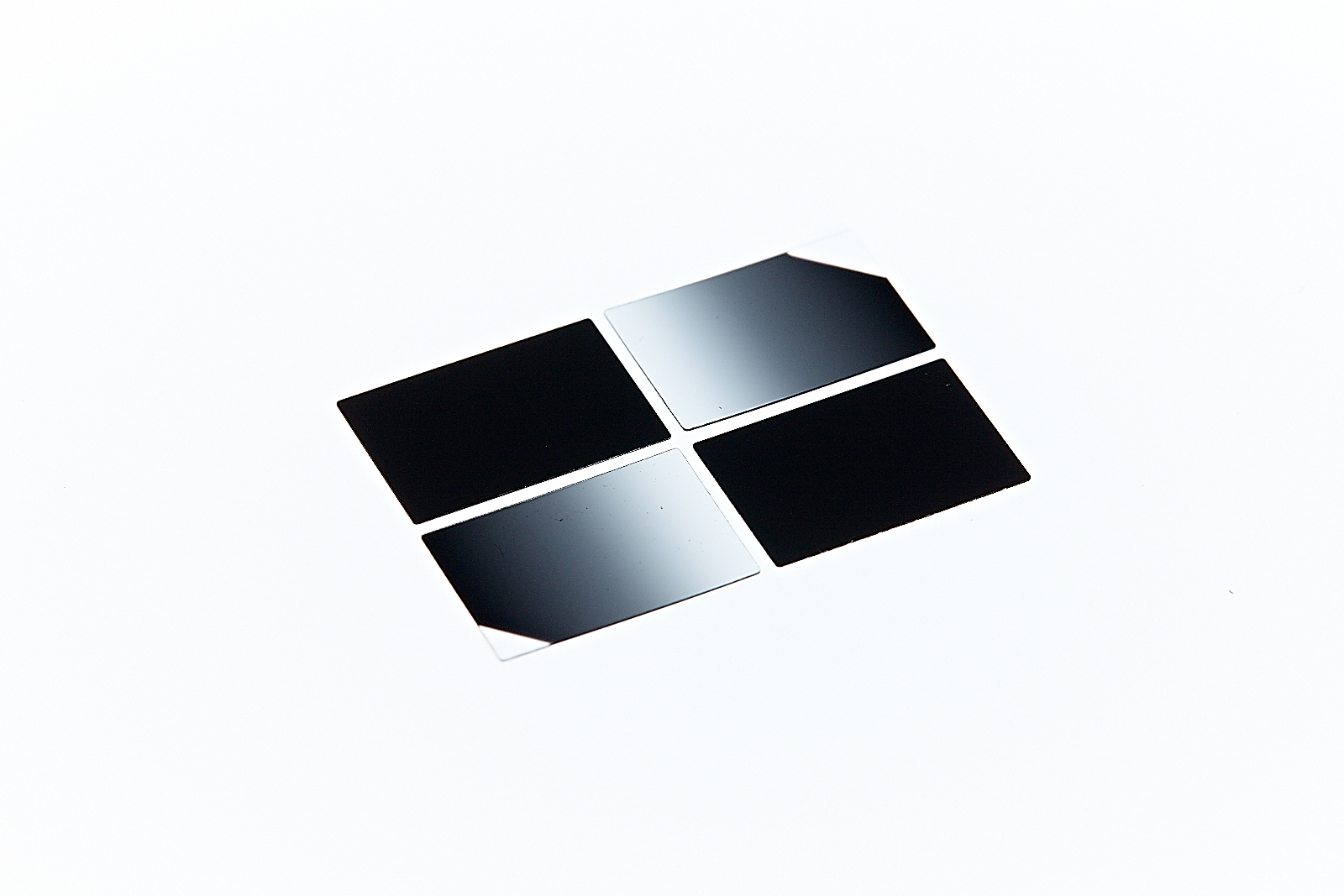

For example, neutral density (ND) filters are used when you want to reduce the intensity of light evenly across the entire image.

Product examples: ND Filter

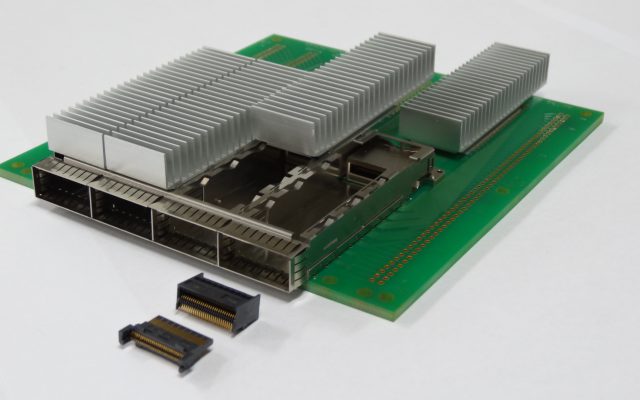

Industrial Equipment Business

When materials such as metals and plastics are welded, intense white light is produced, making it difficult for the human eye to monitor the welding process, which can lead to quality issues.

Infrared camera filters are used in these types of welding processes. These filters allow the specific wavelengths used in laser welding to pass through while reflecting infrared wavelengths toward the camera, making it possible to accurately monitor the welding process.

Product examples: High-power Laser Mirror and High-power Lens AR Coat