Sakura Factory Building No.2 has been completed on the grounds of our production base, in Sakura City, Chiba Prefecture, and begun operation in March 2024.

In this column, we will introduce the interior of Building No.2 and our efforts to reduce the environmental impact.

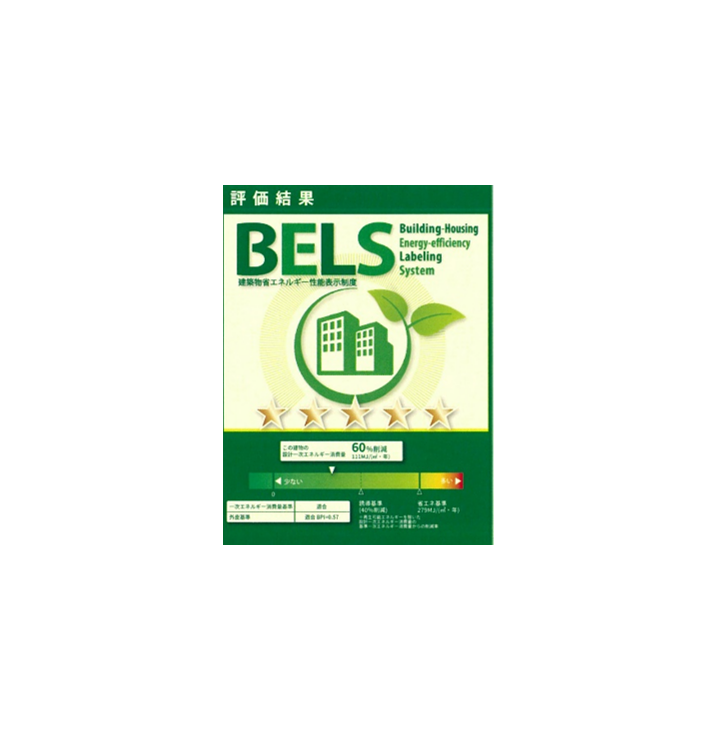

Received BELS

Building No.2 received the highest ranking out of five in the Building Energy-efficiency Labeling System (BELS*1), and was certified as ZEB*2 Ready. The building incorporates exterior wall materials with excellent insulation and fire resistance, highly insulated windows, and energy-efficient electrical equipment.

*1 BELS: Abbreviation for Building-Housing Energy-efficiency Labeling System, a labeling system for the energy-saving performance of buildings launched in 2014 by the Japan Housing Performance Evaluation and Labeling Association. The BEI (Energy Efficiency Index) value is calculated, and a five-level rating is given based on the number of stars. Buildings with excellent energy-saving performance are certified as ZEBs.

*2 ZEB: Abbreviation for Net Zero Energy Building, a building that aims to reduce primary energy consumption through energy-saving measures and achieve zero energy balance through the introduction of renewable energy sources. In the definition, “ZEB Ready” refers to a building that has reduced standard primary energy consumption by 50% or more through energy-saving measures.

Layout to suit our production process

In Building No. 2, the first floor is the press area and the second floor is the plating area, with a layout that allows for efficient production in line with the production flow.

In the press area on the first floor, everything from bringing in materials to pressing, cleaning off the oil used in the press, and heat treatment before plating is carried out. The products are then transported to the plating area on the second floor, where they are plated using chemicals requested by the customer.

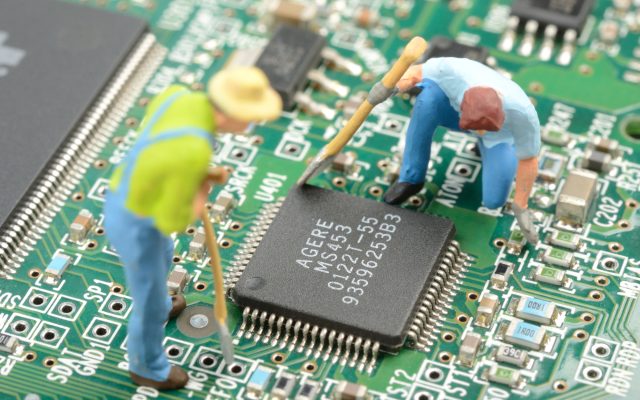

First Floor (press area)

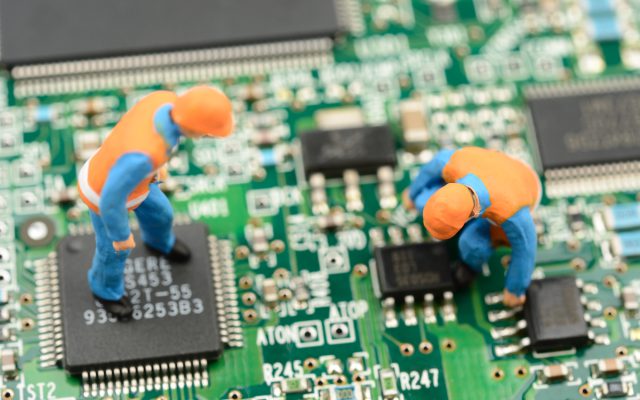

Second Floor (plating area)

Reducing the environmental impact of production processes

In the plating area, products are washed multiple times in each process. The water used for the second and third washing is recycled using activated carbon and ion exchange resin from equipment within the factory as part of a circular economy, and we are working to reduce water usage by using recycled water.

Building No. 2 also takes environmental impact into consideration by cleaning gases generated when using chemicals in a waste gas cleaning device and discharging only clean air outside the factory.

Water Recycling Equipment

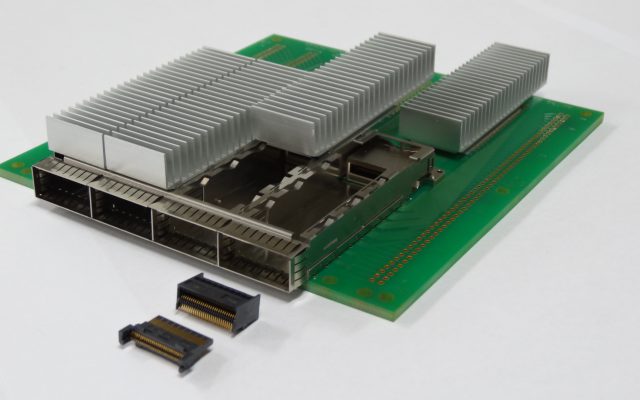

New solar panels installed on the roof

The previous Sakura Factory was equipped with 1,530 pieces of 445W solar panels.

630 pieces of 585W solar panels have been installed on the roof of the newly constructed Building No. 2, and began operation in May 2024. An energy management system that combines these solar panels with NAS batteries* makes it possible for solar power to cover approximately 25% of the electricity consumption of the entire Sakura facility.

The system also supports demand response, managing the amount of power generated by the entire facility in real time and taking measures such as discharging electricity as needed.

*By releasing stored electricity during times of high demand, you can save on your electricity bills and reduce the strain on the power supply.

The Sakura Factory is taking steady steps to reduce its environmental impact and achieve sustainable production. We will continue to make further improvements and promote manufacturing that is friendly to society and the earth.

New Solar Panels